Custom Patch Pricing

PatchProfessionals.com mission is to offer top-quality custom patches at some of the lowest prices you’ll find online. With our team of experienced artists and graphic designers, you’re sure to love the finished product. Simply submit a custom design or request that our artists create a unique patch for you, determine the size of the patch you need, choose an embroidery style, and pick a backing option.

How should I determine the size of my patch?

First, measure the height and width of the custom patch you want to create, then add the height and width measurements. Then, divide that total by two to find the actual patch size which will determine the pricing of your custom patch.

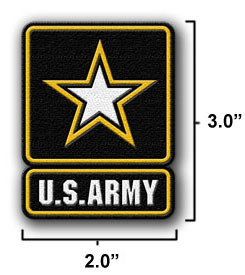

Use this patch to the left as an example. The height is 3.0″ and the width is 2.0″, so we just add those together and get 5″. Now just divide by 2 and we get a 2.50″ patch. We would price this patch out as 2.50″, but the dimensions would stay the same.

Add the length + width and divide by 2.

The patch is 3″x2″, so (3+2)= 5

5/2 = 2.5

The patch size is 2.50″

100% Embroidery (Minimum order – 50 patches)

| Size | 50 | 100 | 200 | 300 | 500 | 1000 | 2000 |

| 2 | $3.18 | $1.89 | $1.10 | $0.97 | $0.77 | $0.67 | $0.59 |

| 2.5 | $3.80 | $2.18 | $1.50 | $1.26 | $1.06 | $0.83 | $0.81 |

| 3 | $4.34 | $2.57 | $1.72 | $1.60 | $1.30 | $0.99 | $0.83 |

| 3.5 | $5.09 | $2.94 | $2.22 | $2.04 | $1.61 | $1.12 | $1.09 |

| 4 | $5.90 | $3.35 | $2.43 | $2.23 | $1.89 | $1.45 | $1.39 |

| 4.5 | $6.79 | $4.06 | $2.81 | $2.66 | $2.17 | $1.67 | $1.55 |

| 5 | $7.80 | $4.54 | $3.57 | $3.13 | $2.35 | $1.97 | $1.84 |

| 5.5 | $9.31 | $5.50 | $4.01 | $3.35 | $2.85 | $2.45 | $2.30 |

| 6 | $11.59 | $6.25 | $5.07 | $4.42 | $3.76 | $3.56 | $3.39 |

| 6.5 | $12.86 | $7.11 | $5.82 | $5.26 | $4.02 | $3.79 | $3.65 |

| 7 | $14.54 | $8.78 | $7.13 | $6.51 | $5.51 | $4.97 | $4.68 |

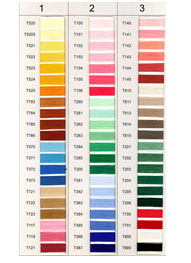

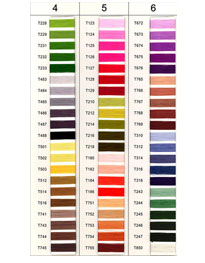

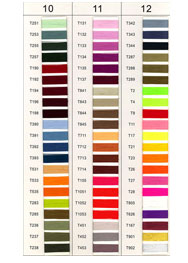

What custom patch backings and thread options are there?